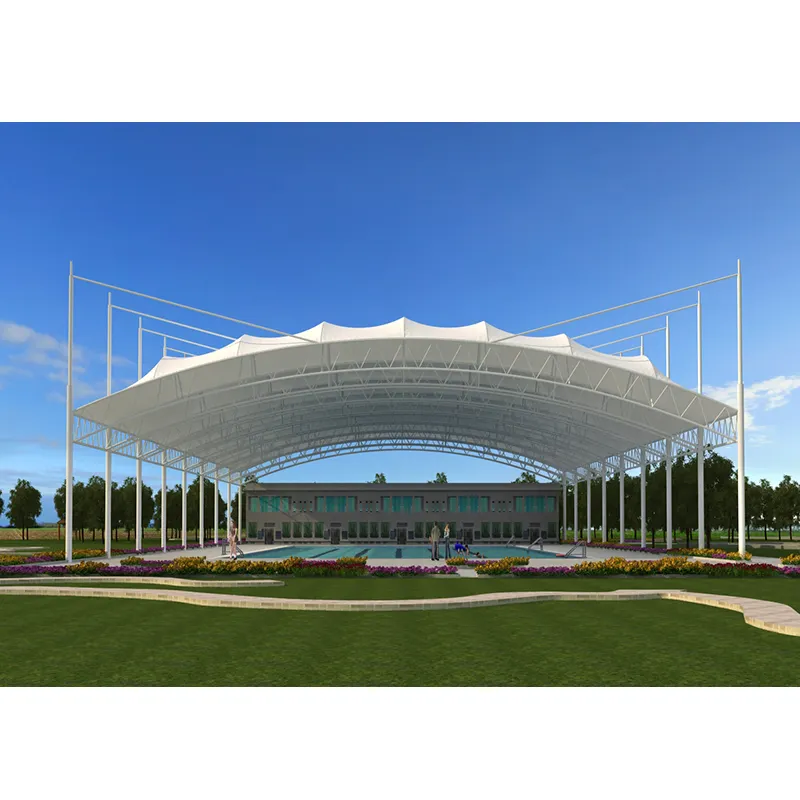

Custom Membrane structure

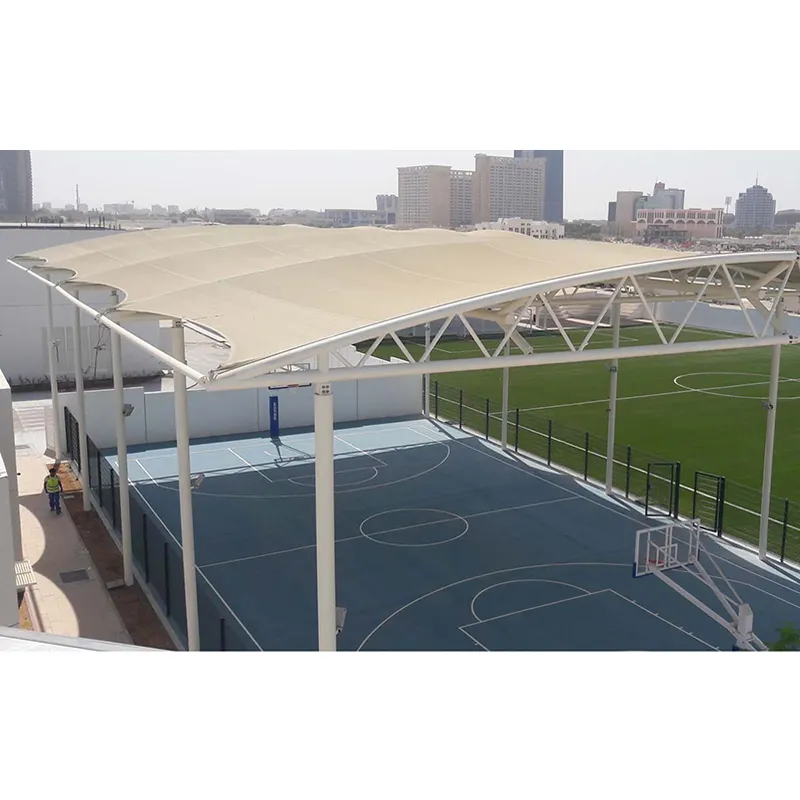

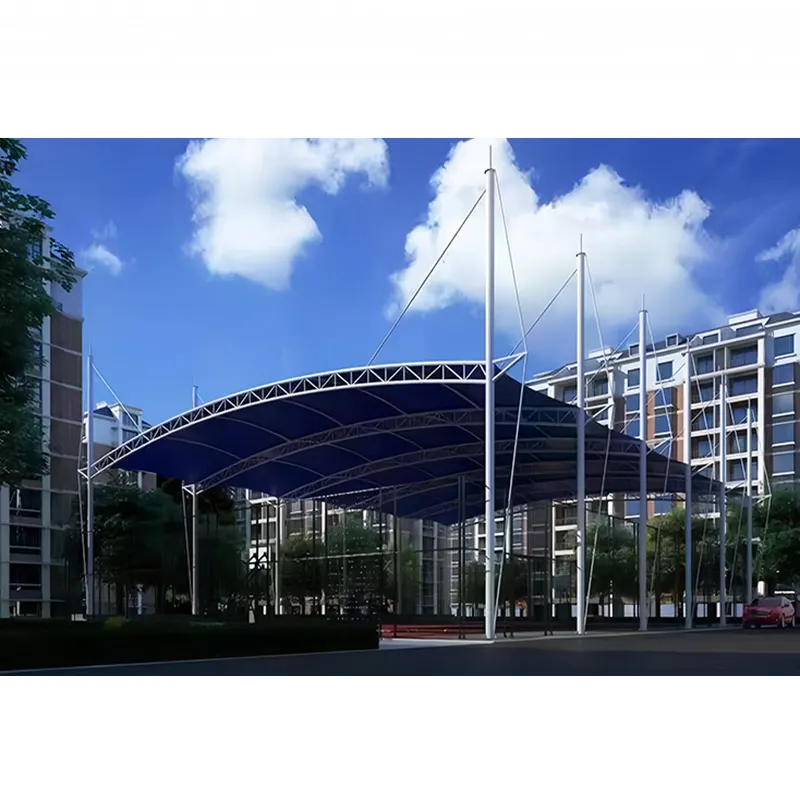

OMD Membrane Structure is a lightweight, high-tension architectural system designed for large-span coverage. With its flexible forms and excellent weather resistance, it combines structural performance with aesthetic impact. Fully customizable in shape, material, and span, it's ideal for sports venues, transportation terminals, commercial pavilions, and public spaces.

- Overview

- Related Products

OMD membrane structures are engineered using high-strength steel or aluminum frameworks paired with durable tensioned membranes such as PTFE, PVC, or ETFE. The system resists UV, wind, and heavy rain, maintaining shape and performance under varying conditions.

Design flexibility is a core advantage—free-form curves, cones, and tensile surfaces can be tailored to the project’s spatial and visual needs. All components are prefabricated, enabling faster installation and lower labor costs. We provide full support for structure calculation, fabric cutting patterns, and connection detailing.

Item |

Specification |

Structural Material |

Steel (Q235/Q345) / Aluminum Alloy (customizable) |

Membrane Options |

PVC / PVDF / PTFE / ETFE |

Lifespan |

PVC: 10–15 yrs / PTFE: 25+ yrs / ETFE: 30+ yrs |

Span Range |

Up to 100m clear span (project-based) |

Surface Treatment |

Hot-dip galvanized / Powder coated / Fluorocarbon coating |

Wind Load Resistance |

≥ 100 km/h (customized to location) |

Snow Load |

Up to 0.5–1.5 kN/m² (design adjustable) |

Fire Resistance |

B1 / B2 class (DIN 4102) / NFPA 701 compliant |

Light Transmission |

5%–40% depending on membrane type |

Applications |

Stadium roofs, parking shelters, transit hubs, exhibition halls, outdoor canopies |

Customization |

Shape, span, membrane material, steel coating, connection system—all customizable |